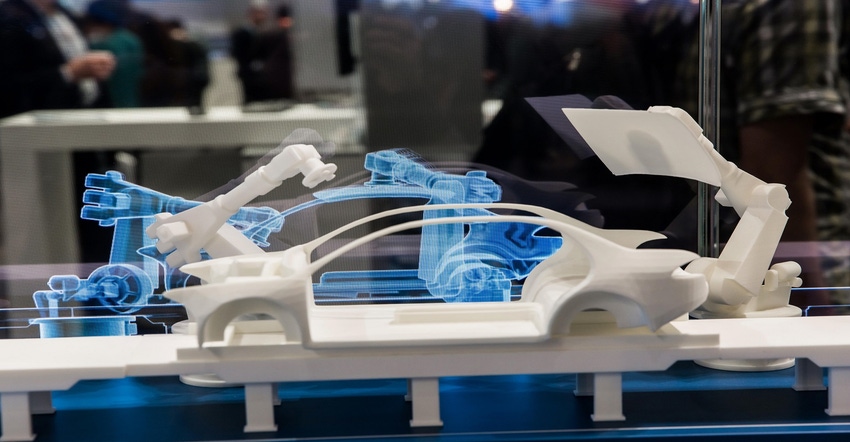

Different digital twin types and tools can create new possibilities for manufacturing.

October 12, 2022

John Pritchard, digital engineering business lead, and Leo Kilfoy, director of SaaS and digital design at Rockwell Automation

Digital twin wasn’t in anyone’s vocabulary when engineers in NASA’s Apollo program used the first “living model” to investigate the Apollo 13 oxygen-tank explosion in the 1960s. Fast forward to today, and digital twins are engrained in manufacturers’ conversations as they plan and implement digital transformation initiatives.

In short, a digital twin is a living digital replica of a physical object or system – and it’s redefining what’s possible in manufacturing. With a digital twin of a machine, for example, you can:

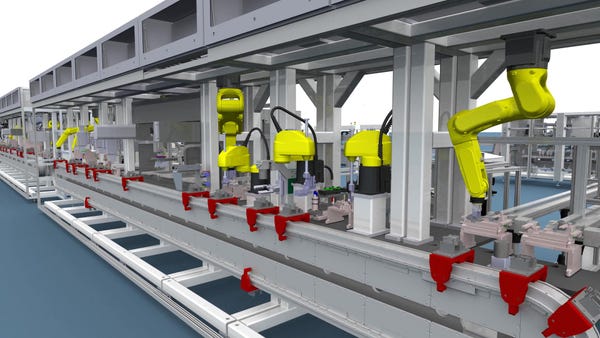

Optimize the machine’s design and refine its performance before you order parts or cut steel.

Test and debug the machine’s controls well before you connect the physical controller and machine at a customer’s site.

Reimagine training, maintenance, and other activities by bringing them into a virtual-reality or augmented-reality (VR/AR) environment.

And yet, despite the high level of interest in digital twins, a lot of confusion remains about what a digital twin is and how to use it. By understanding the concept of a digital twin and the technology that enables it, you can make sure you’re investing in the right tools and putting them to the best use to improve your design processes, your machines, and your customers’ manufacturing operations.

Understanding the Digital Twin

A digital twin isn’t a static digital model. It changes over time just like its physical counterpart based on factors like operating and environmental conditions. A digital twin can also learn. Using historical operating data, it can predict the health and performance of its physical counterpart over time.

There are two types of digital twins to know about – physics-based and data-driven.

A physics-based digital twin is an analytical model that’s built from first principles or our understanding of how the physical world works. Sticking with the example of a digital twin of a machine, the twin is typically built during the design stage from a CAD model. And incorporating control or automation code can help you understand how the machine will behave in certain situations.

With a physics-based digital twin, you can test, tune and prove a machine before you build it. This can reduce your need to build physical prototypes and shorten your development timeline. A physics-based digital twin can also help you deliver better machines by adjusting elements like speed, orientation, and layout until you achieve optimal performance.

Ideally, the digital twin also incorporates other physics, like product loads and environmental stressors. This can help you predict how the machine will perform in different production scenarios and environments.

A data-driven digital twin is built using historical time-series data from sensors. It’s ideal for maximizing the productivity of operational assets.

For instance, a data-driven digital twin can create predictive models to anticipate failures on a machine before they happen. Technicians can then schedule required maintenance during a planned shutdown. You can even use data-driven digital twins to do a rewind and replay of production to review issues that happen and to help improve asset performance.

Physics-based and data-driven twins aren’t mutually exclusive. You can combine them for a wide range of purposes.

For example, a data-driven model can help you calibrate a physics-based model to help make sure it’s producing real-life data. A data-driven model can also provide complex inputs to a physical model. This can help you do a rewind and replay of production issues or test and validate production changes before you make them. One company even runs its orders through these combined models to find the optimal scenarios for its operations.

Physics-based models can also augment data-based models in useful ways. They can train data-based models when insufficient data is available or augment off-nominal conditions. And they can provide an output, like a virtual sensor reading, to help inform system behavior.

Finding the Right Tool for You

The growing demand for digital twins has led to an explosion in digital twin tools on the market. Which one is right for you? When evaluating tools, consider how they:

Support how your teams work: The pandemic has changed work as we know it. More people are working remotely, but they still expect to be able to collaborate with their teams and access the tools they need no matter where they are.

With digital twin tools now available in the cloud along with design and digital engineering capabilities, your teams can access the tools they need no matter where they’re working. Cloud-based tools can also improve collaboration across designers and other stakeholders to increase your speed of innovation. And they allow you to scale on demand by easily adding or removing users and computing power based on project needs.

Ease your access to insights: Unlocking the data you need from your machine to create a digital twin doesn’t need to be a complex process.

Not sure what data to collect? Some digital twin tools can use “smart objects” in a control system to gather data on the most common operating aspects you want to know about – like a machine’s production rate, health, energy consumption, and more. Then, edge gateway software can further save you time and effort by automatically preparing this data and sending it to the cloud.

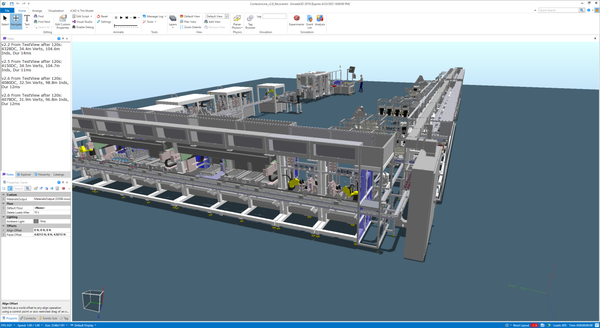

Simplify integration: Expanding the scope of your digital twin from a machine to a system can help you understand and optimize operations at a higher level. But it can also require using multiple digital twin tools. For example, if you’re designing a machine with a robot assembly arm, you may need to use one tool to create the machine’s digital twin and another to create the robot’s digital twin.

In these instances, look for tools that work together. Increasingly, software providers are using standard interfaces to ease information exchange between digital twin tools. Some are even working with each other to create an ecosystem of integrated tools that allow you to combine digital twins at a system level with little or no effort.

A Simple and Accessible Tool

Digital twins once helped solve problems for a multi-billion-dollar space program. Now, they can help engineers in even the smallest machine shops solve their design challenges and optimize every aspect of the machine lifecycle.

Digital twin technology may be complex and daunting, but the tools that allow you to leverage it are increasingly simple, easy to use, and accessible from anywhere. In other words, worry less about what a digital twin is and instead focus on how it can help you be better.

You May Also Like