Packagers Verify Bioplastic Content with Radiocarbon Testing

The prevalence of greenwashing in recent years has driven brand owners to creative solutions — including carbon-14 testing — to prove their plant-based packaging materials are the real deal.

More consumer goods packagers are turning to renewable, plant-based plastic, or a combination of petroleum- and plant-based polymers, for their packaging. A time-honored test method — one linked more closely to archaeology than packaging — can help them prove that the package contains the advertised amount of bio-based plastic. That method is radiocarbon testing.

Typically used to estimate the age of fossils and other ancient organic materials, radiocarbon (aka carbon-14) testing is useful for analyzing plastic materials because of their carbon content.

Using test methods that determine the relative concentrations of carbon-14 isotopes in a packaging sample, technicians can calculate how much of the material is plant-based through the percentage of carbon-14 present — versus petroleum-based.

For example, if a packaging material is found to have 75% carbon-14, the material contains 75% renewable, plant-based plastic and 25% petroleum-based plastic.

Authenticating sustainable packaging claims with scientific proof has grown more important as greenwashing — the practice of making false claims about environmental friendliness — has become commonplace, turning consumers into skeptics.

Sustainability certifications are a way to overcome that skepticism, and some third-party certification organizations rely on the results of radiocarbon testing to authenticate the plant-based and petroleum-based content of a plastic product or package.

The US Department of Agriculture (USDA) BioPreferred Program offers the USDA Certified Biobased Product label, for example, and testing/certification company TÜV Austria provides “OK biobased” certification.

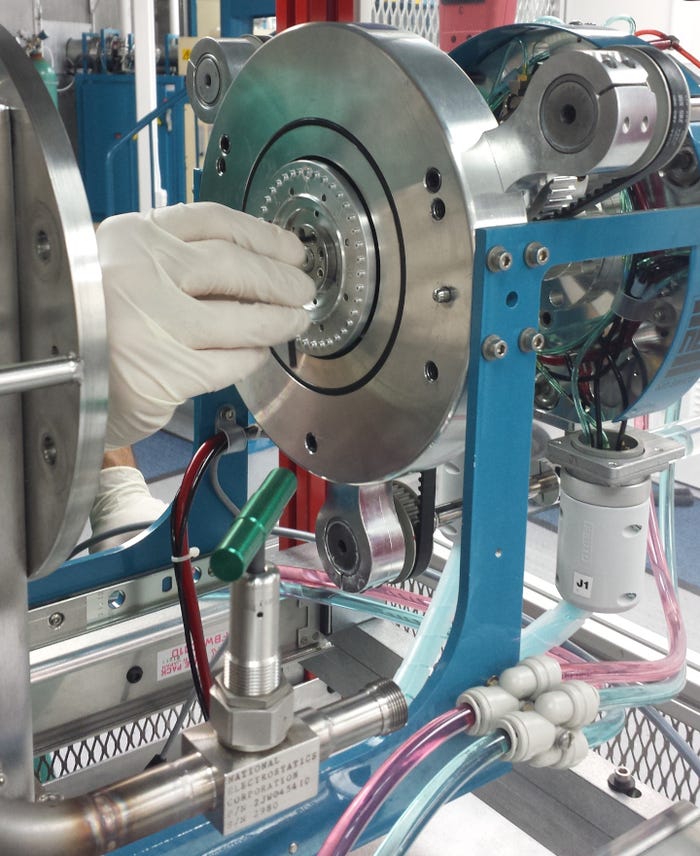

“The USDA BioPreferred Program’s voluntary product label qualification requires ASTM D6866 measurements from a ISO 9001-conformant lab,” says Jordan Turner, marketing coordinator with Beta Analytic, a lab that meets both of these criteria and is one of only two approved testing labs for bio-based-content analysis. Beta uses the accelerator mass spectrometry method to perform radiocarbon testing.

In this exclusive interview with Packaging Digest, Turner answers our questions about radiocarbon testing and explains why packagers are interested in it.

What type of company usually seeks carbon-14 testing to verify bio-based content in its products? A consumer-goods brand owner? Plastic resin producer? Both?

Turner: Suppliers, manufacturers, and distributors of products that are made in whole or part using biomass-derived materials can benefit from carbon-14 testing to confirm the bio-based content of their product ingredients.

Do other companies in the packaging value chain seek this type of testing?

Turner: Carbon-14 testing is useful at several points throughout the product development process. Testing can be performed from the material formulation phase, through R&D and quality control, down to the final product, to determine the bio-based content of packaging and materials.

Why would any of these companies pursue carbon-14 testing of their products — what’s the benefit to them of proving how much bio-based plastic is in their packaging or resin?

Turner: Testing is beneficial in assuring customers a company does not participate in greenwashing, and that packaging is made from sustainable sources.

Bio-based testing provides verification that product packaging is made from biomass-derived materials, providing companies with quantifiable data to validate label claims, increase product appeal, and support marketing initiatives.

What are the benefits of using accelerator mass spectrometry (AMS) versus other test methods for bio-based content testing? What other test methods can be used?

Turner: Carbon-14 testing via accelerator mass spectrometry measures the amount of bio-based material used in a product’s formulation in comparison to petroleum-based alternatives. Other methods include gas proportional counting and liquid scintillation counting, which convert samples to either a gas or liquid form before measuring carbon-14. AMS measurement is the only method that directly measures the amount of carbon in a sample and is considered to be the more efficient method.

The USDA’s criteria for a manufacturer to earn the USDA Certified Biobased Product label is that the product must be tested for bio-based content at an independent, third-party laboratory. Is carbon-14 testing typically (or always) the type of test conducted when a manufacturer wants to prove the bio-based content of a product?

Turner: Carbon-14 testing via the AMS method is conducted in accordance with testing standards such as ASTM D6866, ISO 16620-2, and CEN 16640. Criteria for determining the bio-based content of a product for the USDA requires ASTM D6866 measurements which is always done via carbon-14 testing.

Are plastic resin and plastic packaging eligible for TÜV Austria’s OK biobased certification?

Turner: The OK biobased label is applicable to materials, intermediates, and products with at least 20% bio-based content. To qualify for the OK biobased certification, eligible products are analyzed using carbon-14.

If a product meets the certification criteria, TÜV Austria Bio Preferred issues the certification. For more information on the certification process, visit www.tuv-at.be/green-marks/certifications/ok-biobased/.

About the Author(s)

You May Also Like