15 new packaging solutions vie for your vote

New products drive your packaging innovation machine. Here are more than two dozen solutions exhibitors at the upcoming WestPack 2017 show (Feb. 7-9; Anaheim, CA) submitted for the Packaging Digest Innovation Award competition. You decide which five will become finalists.

The five finalists will make up the stops on our Packaging Innovation Tour at WestPack. Tour attendees will then pick the winner at the end of our innovation expedition.

Read through the following entries (lightly edited for clarity, brevity and magazine style) and then CAST YOUR VOTE HERE. Products are presented here in the order in which they were received. They appear in random order on the ballot.

Photo credit of voting image: Designed by kjpargeter / Freepik

PAGE 1: L301 Small Business Label Printer from Afinia Label

PAGE 2: Intuity Metal Detector from Sesotec Inc.

PAGE 3: TrakSYS 10 MES/MOM software solution from Parsec Automation

PAGE 4: Coated-Metal Electric Label Dispensersfrom Start Intl.

PAGE 5: FormFoil Lite Suture Package from Rollprint Packaging Products

PAGE 6: Redesigned FC filler/capperfrom Serac Inc.

PAGE 7: AD-4961 Series checkweigher from A&D Co.

PAGE 8: New feeder for tabletop printerfrom Color Label Solutions

PAGE 9: CIVCore Software's Dot Print Tool for inspecting ink-jet and other variable codes from Mettler Toledo CI-Vision - [UPDATE 2-9-17: SELECTED AS THE MOST INNOVATIVE PACKAGING PRODUCT AT WESTPACK 2017 BY THE INNOVATION TOUR ATTENDEES!]

PAGE 10: 125mm-diameter squeeze-and-turn CR closure for laundry podsfrom The Plastek Group

PAGE 11: ThermaBar 3 barcode label printer with integrated verification/grading from Verified Printing Systems Inc., part of the ADC Technologies Group

PAGE 12: Unique unit-dose package with wide printable closure from LF of America Corp.

PAGE 13: IoT system for lite-series pharmaceutical filling systems from groninger

PAGE 14: AbleBlock filler/plugger/capper from PallayPack Inc.

PAGE 15: XR75 X-ray inspection system from Anritsu Infivis Inc.

L301 Small Business Label Printer from Afinia Label

Describe your new product.

Labels are an important part of packaging and the Afinia Label L301 Small Business Label Printer contains several innovations.

It is the only printer in its price range (US$1,595) that can print labels that are 8.5-inches wide. It also is the only printer that can simultaneously print with both pigment (B) and dye (CMY) inks. This combines the best of both worlds: the black pigment ink is durable enough for harsh environments while the CMY ink creates colors that are more vibrant than pigment inks.

How does the innovation work?

The L301’s optional unwinder maintains the proper tension across the label substrate, which allows for the even printing of wide labels.

The printhead contains a black pigment cartridge and a dye-based CMY cartridge.

How does your innovation add value?

Product information is typically printed in black text, which needs to be permanent. Shelf appeal is created by excellent label design and vibrant color.

The L301 delivers both in a single printer.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

The L301 in the only sub-$1,600 printer that can produce 8.5-inch wide labels simultaneously using both pigment and dye-based ink.

Intuity Metal Detector from Sesotec Inc.

Describe your new product.

The new Intuity Metal Detector is the newest innovation in metal detection in quite some time. It processes an electromagnetic image of the product to produce even higher levels of detection, forecasts detection compliance and has noise cancellation software unlike anyone has ever seen in a metal detector. In addition, its user interface is designed to be intuitive for use.

How does the innovation work?

The company uses variable-multi-simultaneous frequency technology, as well as creative software and high level mathematics in the electromagnetic image creation. It’s techy in the background to make it intuitive for the operator.

How does your innovation add value?

Added value includes higher levels of food safety not only with being able to detect smaller pieces of metal, but due to the intuitiveness of use. Operators can set it up easily. Plus the detection sensitivity forecast tells the user after a product learns the detection performance. Compliance is important and this device makes it easier to know that you are in compliance.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

• Detection Performance

• Electromagnetic image generation

• Envelope tracing around the shape of the image

• Variable-multi-simultaneous frequency

• Balanced coil for life (low ownership cost)

• Intuitive use

• Noise cancellation (almost complete immunity to vibration)

Include a link to a video that shows us what you’re writing about.

https://www.youtube.com/watch?v=4tZwOKUtYao

TrakSYS 10 MES/MOM software solution from Parsec Automation

Describe your new product.

MES/MOM software solutions have been around for more than three decades. However, the newest solution from Parsec, titled TrakSYS 10, puts the power in the hands of the end-user. The revolutionary TrakSYS 10 uses full web-based configurations, removing the costly burden of implementation. No more expensive implementers or costly coding required. TrakSYS 10 puts the power in your hands.

How does the innovation work?

All installation and component deployment activities are managed through the web-based TrakSYS installation manager application. This tool allows initial setup and configuration of the platform, as well as functions for long-term maintenance, troubleshooting and diagnostics. The installation manager's main screen summarizes the implementation’s health in a variety of key areas such as: database connection information and status, license installation, activation, feature capabilities, and TrakSYS service component registration and running states.

How does your innovation add value?

Often, software license prices are eclipsed by the costs of implementation. Not anymore.

With the lowest TCO (total cost of ownership) of any MES/MOM software solution, TrakSYS 10 removes the burden of expensive implementers and costly coding. Now TrakSYS 10 puts the power in your hands with full web-based configurations.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

The web-based configuration tools of TrakSYS 10 are truly unique in the marketplace. Standard cloud MES/MOM solutions still have lengthy implementation times and really don’t offer much to the client in terms of significantly lower Total Cost of Ownership. By cutting out expensive implementation and costly coding, TrakSYS 10 has the lowest TCO of any MES/MOM solution.

Include a link to a video that shows us what you’re writing about.

https://vimeo.com/185031211/79f8ada5ca

Coated-metal electric label dispensers from Start Intl.

Describe your new product.

Leading tape and label dispensing solution company Start Intl. has launched its new FDA Series of electric label dispensers. The proprietary coating on this line of electric label dispensers was developed primarily for the food and pharmaceutical industries. The first two models in the series are the LD3000FDA and the LD6050FDA.

How does the innovation work?

The proprietary coating (grey) provides superior resistance to metal components subjected to corrosion, as well as erosive and abrasive wear. The coating for the LD3000 FDA and LD6050 FDA is USDA/FDA compliant and CFIA approved.

How does your innovation add value?

Many food and pharmaceutical companies are forced to adhere to USDA and FDA regulations. The new FDA series provides a solution to these requirements.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

We offer the only electric label dispensers in the world with a USDA/FDA compliant coating. This line of label dispensers was designed to assist food and pharmaceutical companies with their applications.

Include a link to a video that shows us what you’re writing about.

https://youtu.be/JhpNPwaYgMU?list=PLuGjgeyPzdx6rIG_Z97OG_GBCYcoq-qkO

FormFoil Lite Suture Package from Rollprint Packaging Products

Describe your new product.

The FormFoil Lite Suture Package is a breakthrough in cold-form foil technology. For the first time, a 0.001-inch aluminum foil structure is able to effectively replace the traditional 0.002-inch aluminum foil composite for demanding suture packages without sacrificing formability and performance. Coupled with AllegroB peelable sealant, the end result is a material that maintains robust formability, reduces consumption of natural resources, provides significant reduction in costs and enhances the user experience.

How does the innovation work?

Surgical sutures are packaged in a three-dimensional aluminum-foil based structure that has demanding requirements. The steep draft angle of the formed bottom is challenging to achieve without initiating cracking, delamination or pinholes in the foil layer. Because the tensile properties of absorbable sutures will degrade when exposed to moisture vapor, any potential loss of barrier is unacceptable. To complicate this further, some grades of sutures are packaged in alcohol. The finished package must be able to hold the alcohol while still allowing a peelable seal.

The industry standard sutures package is a polyester/0.001-inch aluminum foil/copolymer sealant for the top web and a 0.0006-inch oriented nylon/0.002-inch aluminum foil/ copolymer sealant for the cold-formed-foil bottom web. This new suture package structure consists of a top web of polyester/0.00035 aluminum foil/AllegroB sealed to a pressure-formed bottom web of 0.0006-inch oriented nylon/0.001-inch aluminum foil/copolymer.

FormFoil Lite offers two distinct advantages over this traditional suture package (as experienced by the company’s customer Surgical Specialties). For the first time, a 0.001-inch foil layer has been used to create the formed bottom instead of the typical 0.002-inch aluminum foil layer, allowing the aluminum foil thickness to be cut in half without sacrificing forming depth and draft angle and with no degradation in performance. This has allowed our suture customer to meet both cost savings goals and sustainability goals.

The FormFoil Lite Suture Package is designed to be peeled open. Because alcohol is difficult to hold, particularly in a peelable structure, the traditional approach has been to accomplish the peel via delamination. This results in variability in peel strength and no consistent witness mark. With FormFoil Lite, AllegroB has replaced the copolymer in the top web, providing a true peelable seal while still holding the alcohol. Because AllegroB provides a cohesive peel, the seal strength is consistent, making it easy to validate and providing consistent performance to users. In addition, it presents a bright white seal indicator (that is, a witness mark) when peeled to easily confirm a hermetic seal.

The impact of FormFoil Lite extends beyond suture packaging. Due to the reduced cost of FormFoil Lite versus standard formable foils, it’s now possible for cold-form foil package designs to be competitive with other traditional package formats. Using the size of the suture package as an example, the reduced formable package cost of FormFoil Lite package offers a 25% savings over a 2D in-line pouch option and 21% savings over a flow-wrapped option. Additional carbon footprint and shipping savings flow down through the supply stream due to the smaller footprint of a 3D-formable foil package.

How does your innovation add value?

For the first time, a cost-effective version of an aluminum foil structure that has been downgauged by 50% still maintains formability and barrier needed to hold and protect sutures. At the same time, the aluminum foil in the peelable top web was reduced by 65% without sacrificing performance. This technology advancement not only provides cost savings but compounded sustainability benefits. In addition, user experience is enhanced through a high performance peelable sealant capable of holding alcohol.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

Future conservation prospects for FormFoil Lite are limitless. By moving from 0.002-inch aluminum foil to 0.001-inch foil, the costs are in line with the traditional packaging materials used in pouch and flow-wrap applications. Traditional forming foil constructions were generally cost prohibitive. This cost reduction coupled with material footprint reduction savings of 35% over a 2D in-line pouch option and 31% savings over a flow-wrap option for the same size product will make it much easier for companies to meet their sustainable packaging initiatives.

Redesigned FC filler/capper from Serac Inc.

Describe your new product.

The newly designed FC filler/capper is a liquid filling machine redesigned to meet the changing industry needs for a flexible, easy to operate system.

How does the innovation work?

See our YouTube video.

How does your innovation add value?

The system increases operation efficiency through newly designed architecture, as well as a new filling system that is more accurate in net-weight filling. The new design in bottle handling increases the range of bottles that can be handled, as well as reduces tooling changeover time.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

• The open architecture.

• The patented filling algorithm.

• The new anti-drip system.

Include a link to a video that shows us what you’re writing about.

AD-4961 Series Checkweigher from A&D Co.

Describe your new product.

A&D Inspection’s latest checkweigher line, the AD-4961 Series, recently won a Frost & Sullivan award, due to its offering of the following key features and benefits for the packaging industry:

• A newly designed digital load cell and an ultra-high-speed processing module, allowing it to deliver an unmatched level of precision weighing and measurement at 0.08-grams;

• Its standard digital inputs and outputs provide high degrees of user flexibility, allowing for HMI interfacing or the connection of external devices, as well as future expansion to the system;

• A high-visibility touchpanel color LCD screen with a user-friendly interface, including an audio guidance support function;

• Easy upload of product images, to make product identification highly efficient;

• Ability to reach speeds of up to 320 pieces per minute;

• Enhanced protection from dust and water to IP65 standards; and

• A modular design, which allows for quick installation or relocation, and simple maintenance.

How does the innovation work?

The new checkweigher gives end users the ability to increase quality and significantly reduce overall production costs within their operations by minimizing the giveaway of materials above predetermined weights, as well as ensuring compliance by identifying products that are underweight.

“A&D Inspection was able to leverage its proprietary digital signal processing technology (DSP) from our Automotive and other instrumentation groups, and implement those core technologies into our flagship product solutions,” says Terry Duesterhoeft, president/CEO of A&D Americas. “The result has been a new in-motion checkweighing solution that allows our customers to achieve unprecedented quality, affordability, performance and flexibility.”

“With the AD-4961, we are redefining checkweighing by providing technology that achieves or exceeds the results of much more costly equipment,” says Daniel Cannistraci, product manager for A&D Inspection. “We are giving companies a new way to manage their production line processes, especially when it comes to quality assurance and critical control point issues.”

In all, the AD-4961 Checkweigher has four main units, including an in-feed conveyor, a weighing conveyer, a control unit and a base unit. The system also offers a variety of reject options, adding to its versatility. Users also do not need to wait for a service engineer to respond to a system shutdown, as they are able to replace any unresponsive modules and significantly reduce potential downtime.

“This new modular design allows us to serve end users across many different industries, including personal care and cosmetics, food and beverage, machine parts manufacturing and many others,” says Cannistraci.

How does your innovation add value?

According to the Frost & Sullivan report, A&D Weighing stands out for these visionary innovations. It not only updates features and adds options, but also focuses on critical aspects of the user interface and user experience.

A&D Inspection is also among the few equipment vendors that have enough inventory to guarantee delivery within a week, instead of the usual six weeks.

Another important advantage of A&D’s product lines is its software-based equipment. Hardware is often the most expensive component of weighing equipment, which means that maintenance, repairs, calibrations and replacements will be expensive and time consuming. A&D leverages its deep experience in digital signal processing to keep the hardware simple.

With this product line, A&D has targeted specific market segments such as the food and beverage industry, agriculture and fresh food processors. It has penetrated new segments, such as automotive and medical device manufacturing, where precision weighing is required to affordably produce precision auto parts or disposable medical devices.

Furthermore, it has extended its reach to custom packaging and tapped a range of unusual customer segments, such as companies that make commemorative, precious metal coins.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

Based on its recent analysis of the weighing equipment market, Frost & Sullivan recognized A&D Weighing with the 2016 North America Frost & Sullivan Award for Competitive Strategy Innovation and Leadership.

According to Frost & Sullivan, A&D Weighing has emerged as a leading competitor in the North American weighing equipment market based on the strength of its innovative strategy of cost-effective pricing and modular construction for a simple fit into a range of applications. The company also continuously introduces new product lines, ensures rapid delivery, and facilitates quick and easy maintenance and repair of its products.

“The most significant differentiator of A&D Weighing is the high quality of its products. Its microbalances, analytical, and precision balances, as well as industrial bench scales have set benchmarks in quality and often last much longer than rival devices,” says Frost & Sullivan research director Kiran Unni. “Underscoring its commitment to quality, the company also offers a five-year warranty on most of its balances and scales, which is uncommon in this market.”

Include a link to a video that shows us what you’re writing about.

https://vimeo.com/frostsullivan/review/176195686/1c0865519e

New feeder for tabletop printer from Color Label Solutions

Describe your new product.

In 4- and 8-inch print widths, the new Postmark FTF feed system pairs with the company’s PM-417 or PM-836 print engine for a tabletop printing solution for all sorts of media, including but not limited to labels, folded boxes, paperboard, plastic cards, paper bags, paper sheets, envelopes, coasters, tags, cartons, coffee sleeves and postcards. Systems can be configured with either pigment or dye ink in either a 4.17-inch print width (PM-417) or an 8.36-inch print width (PM-836).

The FTF has an integrated feeder, 600mm vacuum conveyor and adjustable receiving tray.

The 8-inch version will be shown at WestPack.

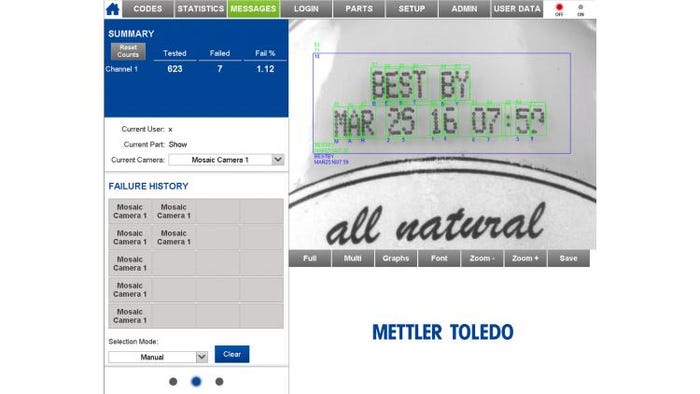

CIVCore Software's Dot Print Tool for inspecting ink-jet and other variable codes from Mettler Toledo CI-Vision

[UPDATE 2-9-17: SELECTED AS THE MOST INNOVATIVE PACKAGING PRODUCT AT WESTPACK 2017 BY THE INNOVATION TOUR ATTENDEES!]

Describe your new product.

Mettler Toledo CI-Vision is integrating inspection tools for detecting ink-jet printing into its powerful CIVCore Software.

Using CIVCore software, installed on the company’s vision inspection systems, provides a strong foundation for a comprehensive vision inspection program.

The latest development, Dot Print Tool, is a unique tool used to detect variable ink-jet printing, providing assurance that every package inspected will have the correct text, sell by or expiration dates applied to packages sent on to consumers. This will help ensure expired products are not sent to consumers, keeping recalls to a minimum and ensuring consumer safety in packaged goods.

How does the innovation work?

The CIVCore Software's Dot Print Tool works by detecting the unique dot matrix pattern displayed by ink-jet printers. When the text is viewed by the software, it interprets the shape of the dots to be a certain character. For packagers to use this product effectively, they can set certain parameters of acceptable text that can pass inspection—for example, certain dates for expiration—and others will be rejected.

How does your innovation add value?

By using the CIVCore Dot Print Tool to inspect expiration dates or lot codes, packagers will be able to automatically reject any misprints in the manufacturing facility. They will able to rework the products onsite to ensure high-quality packages are completed, and eliminate any recalls that may occur had they not had this inspection performed.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

By integrating the Dot Print Tool into the powerful CIVCore software from Mettler Toledo CI-Vision, packagers have a unique tool to inspect variable ink-jet printing on their packages, along with the standard package integrity and label inspection options. With this tool, packagers now have the option to reject non-compliant expiration dates, package warnings, lot codes or other variable data.

125mm-diameter squeeze-and-turn CR closure for laundry pods from The Plastek Group

Describe your new product.

A collaboration between Church & Dwight and The Plastek Group, the new 125mm Diameter Squeeze and Turn CR Closure for Laundry Pods provides child resistance on a large-diameter package.

How does the innovation work?

Squeeze-and-turn child-resistant (CR) closures have been in use for many years in the Drug Formulary area of Pharmacology. The challenge was to adapt a similar solution to a much larger diameter and maintain ease of use without sacrificing CR compliance.

The consumer overrides a lug to unscrew the closure to gain access to the pods. Two offset tabs—separated anatomically—can be squeezed, even by smaller hands, to easily span the lug.

How does your innovation add value?

Child resistance in large-diameter packaging is a challenge. In the relatively new “Pods” laundry category, this new large closure provides easy access to the contents, while ensuring proper child resistance and senior friendly access in accordance with ISO 8317.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

• Product contents are readily accessible;

• The package is intuitive and easy to use;

• The closure is ISO 8317 compliant for child resistance;

• The closure is ISO 8317 compliant for senior friendly access.

Include a link to a video that shows us what you’re writing about.

https://www.youtube.com/watch?v=T5mWeezocVc&feature=youtu.be

ThermaBar 3 barcode label printer with integrated verification/grading from Verified Printing Systems Inc., part of the ADC Technologies Group

Describe your new product.

The ThermaBar 3 printer is a reliable, economically priced industrial direct thermal and thermal transfer barcode label printer with proprietary internal barcode verification and grading that assures a 100% inspection of all barcodes printed. The ThermaBar 3 verifies and grades 1D horizontal and ladder barcodes, and 2D Data Matrix. It also performs data validation on all 1D and 2D codes.

How does the innovation work?

The Thermabar has an integrated / built-in verifier that provides label quality that checks 1D barcodes to the following ISO and GS1 compliance standards: Edge Determination, Decode, Symbol Contrast, Modulation, Minimum Reflectance, Minimum Edge Contrast, Defects, Decodability and Quiet Zone.

2D Data Matrix is verified using the following parameters: Cell Contrast, Cell Modulation, Reflectance Margin, Fixed Pattern Damage, Axial Nonuniformity, Grid Nonuniformity, Unused Error Correction and Print Growth.

When the Thermabar discovers a barcode that does not pass one of the parameters, it will print a void pattern across the top of the label then reprint the label. The number of reprint tries are user selectable, from zero to five before the printer stops.

There is also an optional output for all verification parameter results to be sent to a local PC for archiving.

How does your innovation add value?

With proven return on investment (ROI), the Thermabar provides label quality that will help eliminate customer fines / charge backs for having non-readable barcode labels and reduces the probability of a production line shutdown. It reduces the cost of labor to perform a sampling check for label print quality.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

The verifier is integrated / built into the printer, so nothing is hanging on the outside to be bumped or damaged. The verifier is setup from the control panel on the printer, so there’s no need for an external PC.

Systems are offered in 200, 300 or 600dpi printing resolutions.

Unique unit-dose package with wide printable closure from LF of America Corp.

Describe your new product.

This new unit-dose vial has a large decoration area that can be either labeled, embossed, pad-printed or ink-jet coded.

How does the innovation work?

In current unit-dose packaging, the printable area for product's information is relatively small. Lameplast developed an innovative, patented unit-dose closure that allows companies to provide extensive product information without compromising the convenience of the unit-dose delivery system.

How does your innovation add value?

Brand owners—from pharmaceutical and diagnostic companies to veterinary, cosmetic and food manufacturers—can now include product ingredients and instructions for use on a foldable plastic closure that is part of the packaging itself. This delivers the convenience of a small unit-dose package with the same information of a larger bottle.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

There are currently no unit-dose delivery systems on the market that allow such a flexibility in terms of amount of information and printing/decoration options. Moreover, the foldable area prevents ink or adhesive leaching through the plastic, excluding the risk of product contamination.

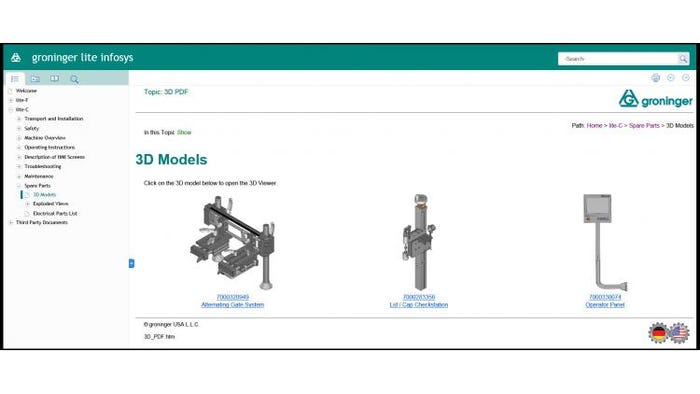

IoT system for lite-series pharmaceutical filling systems from groninger

Describe your new product.

The newest development in one of groninger’s lines is the implementation of a thorough information system called InfoSys, as well as the Internet of Things (IoT) system, to the lite-series filling systems.

The IoT system collects life data of operation time, temperature and speed on a cellphone application for production and maintenance control. Additional information about movement and parts is found in an HMI control. Each screen shows a help button that leads to the InfoSys information system.

This system has 3D views built in the spare parts catalog, which contains 3D pdf files of the complete model for easy part identification.

Include a link to a video that shows us what you’re writing about.

AbleBlock filler/plugger/capper from PallayPack Inc.

Describe your new product.

AbleBlock filling, plugging and capping machine is manufactured by PallayPack Inc. and will be shown for the first time at WestPack 2017.

How does the innovation work?

The compact monoblock system is designed for companies that need to automate but could not justify larger systems. This machine provides automation, which companies are looking for, but drastically reduces the changeparts required for difference size containers, plugs and caps.

How does your innovation add value?

Manual labor is expensive and can compromise quality of the final product. Our machine makes it realistic for users to setup the machine quickly even when production runs are short and changeovers frequent. In the past, users may not have been able to automate. Now, with the AbleBlock, they can!

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

Our solution requires few changeparts for a range of containers, making the machine more versatile, reducing cost and making it easy to changeover from one container to another.

Include a link to a video that shows us what you’re writing about.

Will be available in two weeks. (This really is new.)

XR75 X-ray inspection system from Anritsu Infivis Inc.

Describe your new product.

To answer industry demands to reduce foreign contaminants and decrease, if not eliminate, product recalls, the XR75 X-Ray was launched with its Advanced Long Life Technology.

How does the innovation work?

Advanced Long Life Technology: The highly engineered X-ray generator and sensor provide outstanding sensitivity at lower energy levels. The low-output X-ray generator reduces heat generation, eliminating the need for a cooling system, resulting in a 30% reduction in power consumption. The XR75 can reduce the lifetime operating cost by more than 20%, making X-ray inspection more affordable and reducing the total cost of ownership.

How does your innovation add value?

X-ray inspection technology adds value by detecting contaminants in all packaged and non-packaged foods, beverages and pharmaceutical products. This particular X-ray also saves energy and reduces operating costs.

What distinguishes your packaging product or service from those of competitors and what makes it unique in the market?

The Advanced Long Life Technology is new and innovative in the market.

Include a link to a video that shows us what you’re writing about.

About the Author(s)

You May Also Like