New Packaging Education Hub packs in practical fun

What can packaging engineers learn from Frankenstein? Fancy a look into the future of packaging? Want some useful career advice? We’ve got answers to all this, and a whole lot more, at the new Packaging Education Hub at EastPack 2018 (June 12-14; New York City).

From interactive demos and hands-on activities to edutainment presentations and helpful panel discussions, the three-day educational program at EastPack is free to all event attendees. And registration is free in advance for the show—sign up now by clicking here.

All sessions are in Booth 2385. Here is our full program:

Tues., June 12, 10:30-11:00 a.m.

Assembling a Franken-Line without the Monster Headaches

Most manufacturing operations have a graveyard of unused equipment. Those machines come in handy, though, when a plant has to cobble together a packaging line either in a hurry or on a budget, or both. Learn the pitfalls to avoid and tips to remember when faced with a challenging packaging line assembly project, from a veteran engineer.

Speaker: John R. Henry, CPP, owner, Changeover.com

Tues., June 12, 11:00-11:45 a.m.

The Future of Packaging in the 4th Dimension…and Beyond

In the year 2040, many products will be 3D printed in the home and packaging will be generic or custom designed by the consumer by making simple selections on a screen before hitting “print.” Well…this might be the future, or it might not. Leading consultant, thought leader and packaging futurist Brian Wagner of PTIS teaches us the power of scenario planning to examine probable futures—and plan for your success.

Speaker: Brian Wagner, co-founder and principal, PTIS LLC, and director of Ameripen (American Institute for Packaging & the Environment)

Tues., June 12, 1:00-1:45 p.m.

Just How Hard Is It to Open a Medical Package Aseptically?

Laura Bix, packaging professor for Michigan State University’s School of Packaging, will demonstrate the concept and challenge of aseptic presentation when opening medical packaging. She will provide supplies and a protocol for a live demonstration that would involve having Glitterbug lotion applied to the hands of audience volunteers. These volunteers will then open medical packages, and the packages will be viewed under an ultraviolet (UV) light to measure the amount of contamination that can occur during opening. This topic is particularly relevant because the new European Medical Device Regulations emphasize usability and continuous improvement.

Speaker: Laura Bix, Ph.D., associate director, Michigan State University

Tues., June 12, 2:00-2:45 p.m.

A Comprehensive Look at Integrity Testing Methods for Sterile Barrier Systems

Testing is one of the most challenging endeavors of packaging development. This presentation will offer a comprehensive overview of available integrity testing methods for sterile barrier systems, detailing their operation, sensitivity, and alignment with industry and FDA consensus standards. It will also include results of an industry survey to determine the most popular methods. Take the survey now!

Speaker: Daphne Allen, editor-in-chief, MD+DI

Tues., June 12, 3:00-3:45 p.m.

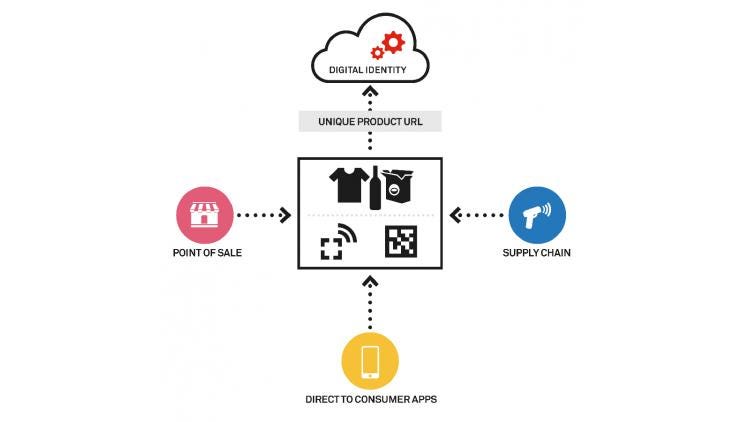

What Does Internet-Enabled Packaging Mean for Brands?

Using today’s newest smart packaging—that is, web-enabled barcodes, including the UPC that appears on every retail package—brands can digitally enhance the consumer’s user experience to build loyalty. In store, consumers can scan the product and access brand content and product information (such as provenance, manufacturing, sustainability, nutrition and care instructions), as well as recommendations and product comparisons, and perform self-checkout. Post-purchase, consumers can scan a product for friction-free reordering, registration or rewards and offers. Learn more about how to use this free technology to leverage the Internet of Things on your packages.

Speaker: Josh Engroff, COO, EVRYTHNG

Wed., June 13, 10:30-11:00 a.m.

Meal-Kit Packaging: How HelloFresh Delivers a Tasty Ecommerce Experience

About 20% of Americans regularly enjoy the convenience of meal-kit cooking—and packaging is a big part of making this possible. In this one-on-one, interview-style chat with the COO of HelloFresh, hear how packaging is helping ecommerce companies leverage today’s opportunities in the perishable supply chain to deliver a high-quality consumer experience. We’ll talk about product freshness and safety; portion control and health-and-wellness; and sustainability.

Speakers: Uwe Voss, chief operating officer, HelloFresh

Lisa McTigue Pierce, executive editor, Packaging Digest

Wed., June 13, 11:00-11:45 a.m.

Emerging Technologies in Packaging + Design

Attendees will encounter three digital innovations that are disrupting packaging and design in an immersive, hands-on session spent playing with color virtualization, augmented reality, analytical tools and computer vision. Participants will walk away with first-hand experience using some of the latest apps and technologies, ideas for saving weeks in the packaging process, and a new frame of reference for “what’s possible.”

Speaker: Danielle Sauvé, director of customer experience and insights, Danaher, Product Identification Platform

Wed., June 13, 1:00-1:45 p.m.

Can You Find the Fake?

Whether you market pharmaceuticals, cosmetics, spirits, or essentially any product with a fan base, your products’ supply chain could face counterfeiting and diversion risks. You’ve got a range of anti-counterfeiting technology options from which to choose, and here’s your chance to try out a few. This interactive session will provide an overview of the risks and available solutions and then challenge you to identify suspect products using some of the tools of the trade.

Speaker: Karl Hoelper, director of marketing, CCL Healthcare

Wed., June 13, 2:00-2:45 p.m.

Upcycle That Package—Live!

Create your own treasure from trash in this fun and engaging hands-on activity that helps you explore end-of-life options for hard-to-recycle packaging. An industrial designer from TerraCycle will walk you through the upcycling process, and then you’ll be able to make your own memento to take home from used and empty packaging that will be cleaned and prepped for this project.

Speaker: Kelsey Moffitt, industrial designer, TerraCycle

Wed., June 13, 3:00-3:45 p.m.

Beyond the Baggie: The Future of Cannabis Containers

How can design and packaging change the image of recreational cannabis?

Learn about industry specific issues that are facing this budding (pun intended) market

A discussion on what the future of this industry could look like

Speaker: Walter Apodaca, founder/CEO, Gizmo Beverages Inc.

Thurs., June 14, 10:30-11:00 a.m.

Packaging Equipment Development Process Safety: “Missing Parts”

Food companies are constantly implementing capital improvement projects for process and packaging equipment. Whether the equipment and processes supported therein include automation, robotics, artificial intelligence or are simply basic operator-supported, pneumatic and electro-mechanical PLC controlled devices, a team approach to design safety risk and hazard assessments and must be developed and applied to insure the continuous production of safe packaged foods. The process, with similarity to HACCP/HARPC, uses the expertise of multiple involved and required functions, each with the expertise to identify applications, complexity, risk and the hazards that will need to be mitigated by design criteria, specifications and oversight. Expert communication and documentation partnership between client and equipment supplier are necessary to produce a safe, effective (equipment) process built to produce single or multiple products of safely and hygienically.

Speaker: Gary Kestenbaum, food packaging safety consultant, Gary Kestenbaum, Packaging Consultant, Inc.

Thurs., June 14, 11:00-11:45 a.m.

Sustainable Packaging from Plants

Anellotech is a sustainable technology company pioneering the Bio-TCat Process for the production of cost-competitive renewable chemicals from non-food biomass to provide the path to sustainable packaging. Materials made from these bio-based aromatic chemicals (benzene, toluene and xylenes, “BTX”), such as polyester, polyurethane, polycarbonate and ABS, are used in consumer applications for packaging, outerwear, automotive, carpets, detergents and more. Bio-TCat’s cost-competitive advantage results from the use of non-food biomass, such as wood or agricultural residues, and an efficient and economical catalyst as the only significant inputs.

Anellotech is collaborating with its strategic partners Suntory, Toyota Tsusho, IFPEN, Axens and Johnson Matthey for the development and commercialization of the Bio-TCat Process. The alliance with Suntory, one of Anellotech’s principal strategic investment partners, began in 2012 with the goal of enabling the development and commercialization of cost-competitive 100% bio-based plastics for use in beverage bottles. Suntory currently uses 30% plant-derived materials for its Mineral Water Suntory Tennensui brands and is pursuing the development of a 100% bio-based PET bottle through this alliance, as part of its commitment to sustainable business practices.

Anellotech founder, president and CEO Dave Sudolsky will discuss the company’s progress towards commercialization, as well as the broader packaging applications for Anellotech’s innovative technology.

Speaker: David Sudolsky, president, Anellotech

Thurs., June 14, 12:00-12:45 p.m.

5 New Packages that Tell Awesome Sustainability Stories that Don’t End There

L’Oréal, Amazon, Blue Bunny, Tea of a Kind and Replenish introduced new packages this year with strong sustainability features—on top of convenience features and functional designs to boost the user’s experience with the brand. Lively case studies showcase why these companies got “it” right and how you can follow their lead.

Speaker: Lisa McTigue Pierce, Executive Editor, Packaging Digest

Thurs., June 14, 1:00-1:45 p.m.

Packaging Trends that Really Matter and Why

Internet of Things (IoT), ecommerce, sustainability and other current and emerging trends in packaging directly impact the day-to-day tasks of packaging professionals. Our panel of experts will discuss today’s packaging trends that really matter as “Customer Experience” becomes the ultimate goal and “Brand Affinity” becomes the coveted prize.

Panelists: Erik Holm, packaging development manager, McCormick & Co. (joining remotely);

Matt Dingee, co-founder/president/COO, OnPoint 2020 (previously with Campbell Soup)

Kelly Murosky, packaging engineer, Seventh Generation;

Andrew Krekling, packaging engineer, Tyson Foods;

Sara Shumpert Dunn, director, The Packaging School;

Moderator: Lisa Pierce, executive editor, Packaging Digest

Thurs., June 14, 2:00-2:45 p.m.

Rising to the Challenge of a Packaging Career

Packaging is a great career, as it taps into different disciplines—the creativity of design and the logic of engineering. And, as a dynamic industry, it’s ever changing. However, such diversity and constant change also present challenges. Living in the trenches, our panel of next-generation packaging leaders will share some of the difficulties they have been encountering in their careers, as well as lessons and helpful tips they’ve learned along the way.

Panelists: Erik Holm, packaging development manager, McCormick & Co. (joining remotely);

Matt Dingee, co-founder/president/COO, OnPoint 2020 (previously with Campbell Soup)

Kelly Murosky, packaging engineer, Seventh Generation;

Andrew Krekling, packaging engineer, Tyson Foods;

Moderator: Sara Shumpert Dunn, director, The Packaging School

About the Author(s)

You May Also Like