Optimization

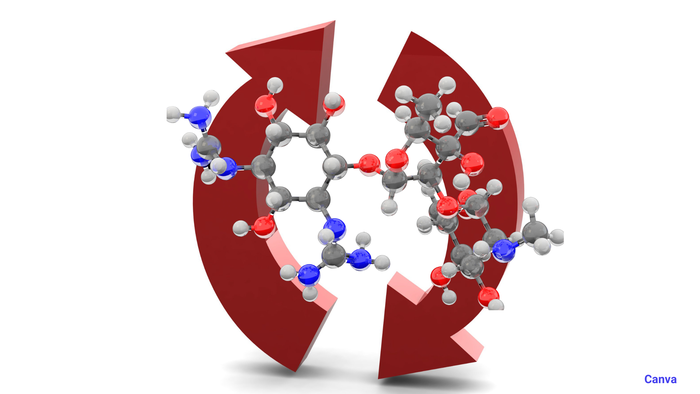

Graphic of earth vs. plastics

Sustainability

Planet vs. Plastics: Not All Plastic Problems Are the SamePlanet vs. Plastics: Not All Plastic Problems Are the Same

A focus on three core areas and four polymers will minimize the environmental impact of plastic and microplastics now and in the long term.

Sign up for the Packaging Digest News & Insights newsletter.